Bal-tec™ Home Flexible Ball Gages

Flexible Ball Gages

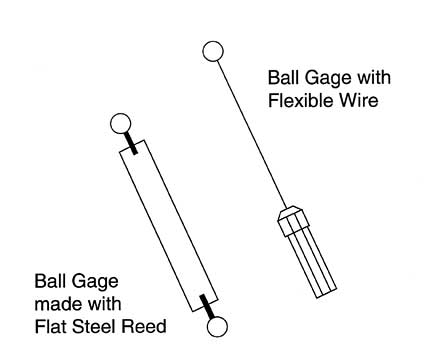

There are two general designs of flexible ball gages. The first and by far the most common flexible ball gauge is a precise ball of the desired size with a length of piano wire glued into a close fitting hole that has been drilled into the ball by the Electrical Discharge Machining process.

The flexible wire can be any desired length. This design will obviously be equally flexible in all directions. This is the least expensive approach. The second design has the gage ball fixed to a thin flat reed of spring steel. The characteristic that sets this design apart is that the position of the ball is extremely flexible in one plane and perfectly rigid in a plane 90 degrees to that. In this way, the ball can be guided between the gap to be measured without any binding. This is a much better design for long flexures.

The ball can be attached in several ways. On larger balls the narrow slot can be machined into the ball using a wire E.D.M. machine and the ball is glued on with high strength epoxy glue. An alternative is to drill a hole in the ball and glue it onto a cylindrical pin that is then slotted with the wire E.D.M. machine. Then, this is glued on the flat spring steel reed. We stock flat flexures in ¼ inch (6.4mm) and ¾ inch (19mm) widths that are 0.012 inch (0.3mm) thick.

With all of the extra work involved in this design, it is obviously a more expensive product.