Bal-tec™ Home Master Ball

Master Ball

Gage Ball — Inspection Balls Master Ball Gage — Master Sphere — Ball Master — Ball Setting Master

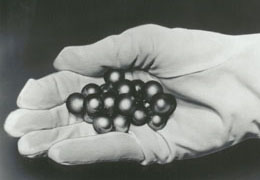

The concept of the “Master Ball” is well-established and time-proven. Gage balls, or Master Balls, are very high quality spheres that are perfectly round to less than ten-millionths of an inch (250 nanometers) with a sub micro-inch surface finish. These balls are calibrated absolutely. Absolutely means two things: That it is a direct reading traceable to the speed of light--not a comparison measurement. And second, that the size is corrected for all Hertzian elastic deformations due to the contact force of the measuring machine. The two materials usually used for master balls are a very high carbon chrome alloy steel that is hardened to at least 60 HRC or Tungsten Carbide of the 94% T.C. and 6% cobalt type.

The best application is to use a Master Ball of good geometry and well known size as the setting master to compare with balls to be measured. In the same way, the Master Ball can be used to accurately set a comparator gage to precisely measure parts. Master balls also find wide use for determining the pitch diameter of worn gears, the angle of internal tapers, the internal cylindrical diameters of holes, the dimensions of dovetails, and the pitch diameter of internal threads. They are popular for measuring the depth and angle of countersinks. They can be attached to a stem to form a ball plug gage which can be used to measure the gap between the elements of an assembly, the cross-race curve of a bearing race, the inside diameter of tubing, or to simply determine the diameter of a cylindrical hole. With a threaded stem attached to the master ball, it can be connected directly to an indicating gage for more efficient use.

Quality

Generally speaking, the quality of a Master Ball is AFBMA Grade 10 or better with the exact size calibrated. The concept of the “Master Ball” is entirely functional, but it really is not in step with the modern concept of dimensional metrology. The modern approach is to develop an error budget that includes all of the systematic and random errors of the entire measuring process. This includes the setting master, the indicating gage, the environment and the operator. In this way you can assign a definable uncertainty to the entire measuring process.