Bal-tec™ Home Cubes to Balls

Cubes to Balls

Balls Ground From Cubes

Materials that can’t be, or are very difficult to machine, by any conventional methods can still be economically processed into precision balls. Some of the materials that lend themselves to this technique are: Borosilicate Glass, Colored Glass, Gallium Phosphate, Inconel® X from plate stock, Optical Glass, Soda Lime Glass, Titanium Carbide, Sapphire, Silicon, Tungsten, Tungsten Carbide, various ceramic and cermets, and Zerodur®.

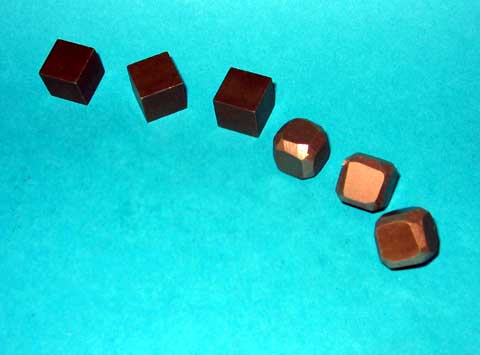

Blocks of the chosen material are first sliced into plates using an internal diamond slicing machine. (See Figure #1.) The plates are then cut into very symmetrical cubes, using thin diamond wheels. The terminology for this process is, not surprisingly called, “Slicing and Dicing”. (See Figure #2.)

The corners of the very precise cubes are slowly ground off until a high quality ball is finally generated. The ultimate quality of these balls is just as good as those produced by conventional means.